PVDF Weld Neck Flange

Name: PVDF Neck-weld flange

Material: PVDF (100% virgin material)

Pressure level: 0.6MPa ,1.0MPa

Jointing: Welding

Color: White

Standards: ISO10931

Brand: New Golden Ocean

Origin: Jiangsu, China

Density: 1.17~1.79gcm3,

Melting point: 172℃

Long-term working ambient temperature range: -40~150℃

Thermal deformation temperature: 112~145℃

Oxygen index: 46%

Crystallinity: 65%~78%

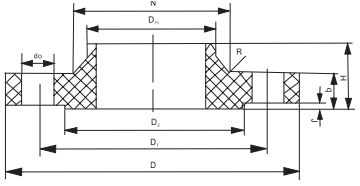

| Weld neck flange | |||||||||||

| Nominalouter

diameter De |

Outerdiameter

DH |

Flangeouter

diameter D |

Bolt holecenter

circle diameter D1 |

Bolt holediameter

do |

Bolt | Flangethickness

b |

Flangeheight

H |

Sealing surface | Flange neck | ||

| D2 | f | N | R | ||||||||

| 32 | 32 | 120 | 85 | 14 | 4-M 12 | 16 | 60 | 68 | 2 | 46 | 4 |

| 40 | 40 | 140 | 100 | 18 | 4-M 16 | 18 | 60 | 78 | 2 | 62 | 4 |

| 50 | 50 | 150 | 110 | 18 | 4-M 16 | 18 | 60 | 88 | 3 | 70 | 6 |

| 63 | 63 | 165 | 125 | 18 | 4-M 16 | 20 | 60 | 102 | 3 | 86 | 6 |

| 75 | 75 | 185 | 145 | 18 | 4-M 16 | 22 | 80 | 122 | 3 | 104 | 6 |

| 90 | 90 | 200 | 160 | 18 | 4-M 16 | 24 | 80 | 138 | 3 | 118 | 6 |

| 110 | 110 | 220 | 180 | 18 | 8-M 16 | 24 | 80 | 158 | 3 | 140 | 6 |

| 125 | 125 | 220 | 180 | 18 | 8-M 16 | 24 | 80 | 158 | 3 | 140 | 6 |

| 140 | 140 | 250 | 210 | 18 | 8-M 16 | 26 | 80 | 188 | 3 | 168 | 6 |

| 160 | 160 | 285 | 240 | 22 | 8-M 20 | 28 | 80 | 212 | 3 | 195 | 8 |

| 180 | 180 | 285 | 240 | 22 | 8-M 20 | 28 | 80 | 212 | 3 | 195 | 8 |

| 200 | 200 | 340 | 295 | 22 | 8-M 20 | 34 | 100 | 268 | 3 | 246 | 8 |

| 225 | 225 | 340 | 295 | 22 | 8-M 20 | 34 | 100 | 368 | 3 | 246 | 8 |

| 250 | 250 | 395 | 350 | 22 | 12-M 20 | 38 | 100 | 320 | 3 | 298 | 10 |

| 280 | 280 | 395 | 350 | 22 | 12-M 20 | 38 | 100 | 320 | 4 | 298 | 10 |

| 315 | 315 | 445 | 400 | 22 | 12-M 20 | 42 | 100 | 370 | 4 | 350 | 10 |

| 355 | 355 | 505 | 460 | 22 | 16-M 20 | 46 | 120 | 430 | 4 | 400 | 10 |

| 400 | 400 | 565 | 515 | 26 | 16-M 23 | 50 | 120 | 482 | 4 | 456 | 10 |

| 450 | 450 | 615 | 565 | 26 | 20-M 24 | 50 | 120 | 530 | 4 | 502 | 12 |

| 500 | 500 | 670 | 620 | 26 | 20-M 24 | 52 | 120 | 585 | 4 | 559 | 12 |

| 560 | 560 | 730 | 675 | 30 | 20-M 27 | 54 | 160 | 635 | 5 | 610 | 14 |

| 630 | 630 | 780 | 725 | 30 | 20-M 27 | 58 | 160 | 685 | 5 | 680 | 14 |

1.Superior Material Performance:

Crafted from high-performance polyvinylidene fluoride (PVDF), Jiangyin Huada’s Neck-weld Flange ensures exceptional material properties, including corrosion resistance, thermal stability, and durability. This contributes to a reliable and long-lasting solution for pipeline connections.

2. Compact and Efficient Design:

The Neck-weld Flange features a compact design with a unique neck structure, optimizing the welding process for enhanced stability during connection. This design not only strengthens the connection but also provides outstanding sealing performance, ensuring a secure and leak-free system.

3. Robust Welding Connection:

Through the welding process, the PVDF weld neck flange establishes robust connections, which can prevent leaks and connection failures during operation. This ensures the stability and reliability of the pipeline system, even under demanding environmental conditions.

4. Emphasis on Sealing Integrity:

Specifically designed for pipelines requiring high-sealing and stable connections, the PVDF weld neck flange directly welds with the pipeline, reinforcing stability and sealing at the connection points. This meticulous focus on sealing integrity ensures a secure and efficient operation of the system across diverse operating conditions.

1. Chemical engineering: used to transport corrosive chemicals such as acids, alkalis, solvents and oxidants

2. Semiconductor manufacturing: used to transport high-purity chemicals and corrosive gases

3. Water treatment: used in water supply and wastewater treatment fields, including the transportation of corrosive chemical reagents, gases and drinking water

4. Mining and metallurgy: used to transport acidic and alkaline slurries, chemical reagents and high-temperature liquids

5. Sanitary engineering: used to transport high-purity water, medicines and food, such as pharmaceuticals and food processing

6. Electroplating industry: used to transport acidic and alkaline solutions and various electroplating chemicals

Inco-terms: EXW, FOB, CRF, CIF

Packing: Standard export wooden case, Carton, or as your request

Staring Port: Port of Shanghai or as your request

Lead time: 15-30 days after confirming the order

Transportation method: Sea, Railway, Air, Express delivery, etc.